Sorting solutions

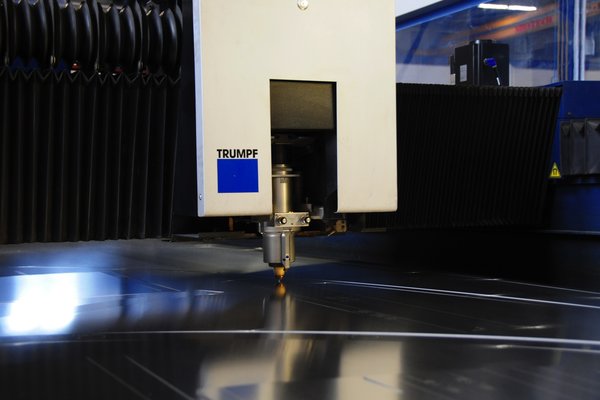

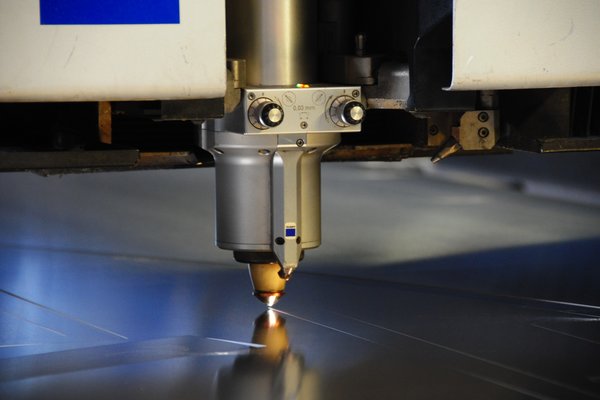

On our laser cutting department we operate with 5 Trumpf laser cutting machines with a maximum cutting range of 12x2.5 m1 and a capacity of 10kw kilowatt.

Our machines are equipped with fast exchange tables and loading robots for optimal logistics and sorting solutions.